In the early morning hours, when the humidity in the basement of Cornell’s Bard Hall was just right for her graduate research, Rachel Dorin, Ph.D. ’13, could be found meticulously casting polymer membranes. More than a decade later, Dorin is still producing membranes, but now they’re for some of the most prominent biotechnology and semiconductor manufacturing companies in the world.

Rachel Dorin, Ph.D. ’13, co-founder and CEO of TeraPore Technologies.

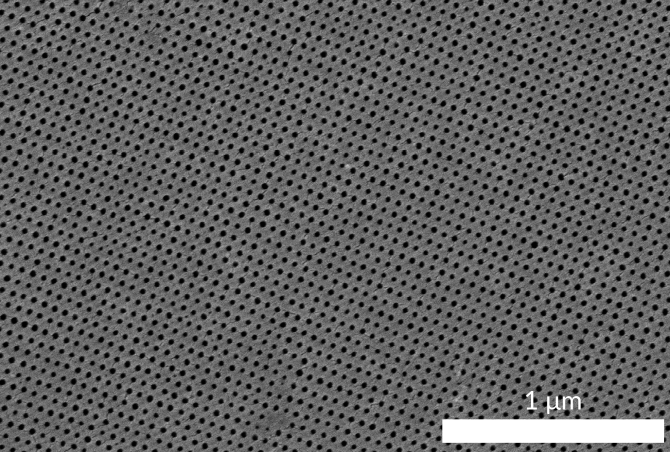

Dorin is co-founder and CEO of San Francisco-based TeraPore Technologies, which launched in December its first line of novel nanofiltration products based on the company’s trademarked Intelligent Membrane platform that uses tunable self-assembled block copolymers. Rooted in her research at Cornell, the filters are changing how the pharmaceutical industry is reducing risk of harmful virus contamination in biological drugs.

The company is hitting the market at a critical time when new therapeutics, such as anti-cancer immunotherapies and antibody-drug conjugates, face challenging and costly hurdles in the manufacturing process, according to Dorin.

“It’s very difficult to filter out unwanted viruses from these new drugs because each drug has unique macro-molecular interactions with each other and with the polymeric membranes that can lead to filterability challenges,” said Dorin, who studied materials science and engineering at Cornell while earning a minor in business from the SC Johnson College. “Our filter is designed to overcome these manufacturing challenges and give our users robust and consistent performance.”

Microscopy of a self-assembled isoporous membrane with highly uniform structure, developed by TeraPore Technologies.

The surface chemistry and membrane structure of TeraPore’s trademarked IsoBlock VF filters, launched in 2023, were developed to optimize performance across a wide range of processing conditions, a critical attribute for this step of the purification process.

“As an academic with a deep love for research, there is nothing more rewarding than to see a technology that was first developed in the lab by a graduate student making it into a product led by that same student,” said Uli Wiesner, the Spencer T. Olin Professor of Engineering and co-founder of TeraPore who serves on its scientific advisory board after having been Dorin’s advisor at Cornell. “It has been incredible for me over the years to see Rachel grow in these different roles and I can’t wait to see how her exciting story will further evolve.”

Dorin said the road from bench to market was filled with many obstacles, but that her education at Cornell prepared her to lead the company through them.

“At Cornell I was surrounded by all these brilliant people trying to solve hard problems and there was just so much camaraderie, I felt like I was part of a family,” Dorin said. “That’s something I’ve tried to bring to TeraPore, that feeling of being on a team.”

Dorin added that marketing TeraPore’s products to a niche industry was also part of her journey bringing a Cornell technology to the market. As a way to showcase the rigor and the development that went into them, the syringe filters come in packaging evocative of a high-end smartphone or computer.

IsoBlock VF Syringe Filter Evaluation Kit, a trademarked product of TeraPore Technologies.

“We did that because our filters are different, but you can’t see the nanoscale attributes with the naked eye. We wanted to signal that the technology that’s inside is very valuable and innovative,” Dorin said.

Leveraging this technology, TeraPore has developed a suite of virus filtration products that can address complex separation challenges from the initial stages of drug development all the way to full-scale production. And Dorin is enthusiastic about new products being developing in both the bioprocess space and other high-impact industries.

“We’re working on separations where removing nanometer size contaminants becomes mission-critical. We believe that this versatile technology platform is going to continue to have an outsized impact on the way the world works,” Dorin said. “It continues to fascinate me how one can take something so fundamental from a university and have a such a huge impact globally. I find it very rewarding.”

Meanwhile, Wiesner’s research group is also continuing to fuel further advancements in separation technologies.

“At Cornell we are continuing to push our fundamental understanding of what can be done with block copolymer self-assembly in the field of ultrafiltration membranes,” Wiesner said. “Advances in science always drive exciting innovations.”

Syl Kacapyr is associate director of marketing and communications for Cornell Engineering.